Login / Register

Shigeru Shiratake, corporate vice president of DRAM, Emerging Memory Process and Integration & Device Technology at Micron, shares insights into the development of and updates on shipment of Micron’s market-leading 1β (1-beta) DRAM technology. Micron is now shipping first-in-market qualification samples of LPDDR5X technology developed on next-generation process node technology to smartphone manufacturers and leading chipset suppliers.

Micron innovates — from alpha to beta

Micron has been the DRAM market technology leader since it was the first supplier to begin shipments of DRAM manufactured on 1α (1-alpha) process technology in January 2021. On May 12, 2022, Micron shared the first insights on the next generation of advanced DRAM technology.

The new 1β DRAM technology is an advancement beyond existing leadership on 1α DRAM-based products. The technology is ready, ramping and now shipping in the form of LPDDR5X qualification samples to our leading smartphone manufacturers and chipset partners. This is a critical milestone and allows Micron and our partners to move forward to bring new performance and better power efficiency to the next wave of innovation and compelling use models for smartphones.

Along with processor technology and storage technologies, memory has been a key driver in the evolution of technology. Any services accessed via the cloud and virtually any devices considered “smart” require memory technology. From the ability to support camera technology in the earliest cell phones to the introduction of tablets, thin and light laptop computers, and wearables, memory technology has been a key enabler. Without processors being able to rapidly access applications and data, the evolution of technology and delivery of new user experiences are greatly hampered. With each successive advancement in process technology to shrink cell and transistor size, Micron enables increased memory density, improvement in power efficiency and increased performance, helping to unlock new opportunities for digitization, optimization and automation. While the future is difficult to predict, based on mobile customer interest, we believe the next generation of 1β-based DRAM will unlock an exciting new world of technology use cases and business advantages.

Tiny development leads to bold leadership

For those who may not know, semiconductors are developed in highly detailed processes and with specialized tools that are in aggregate termed nodes. These nodes are used to manufacture a generation or more of new products — such as DDR5, DDR4, LPDDR, GDDR and more. Typically, each node progression represents a further shrinking of the smallest components of the transistors and capacitors of the die, as well as advanced CMOS adoption.

In this case here, our new 1β process technology represents a reduction in size and power consumed per transistor compared to DRAM build on our prior-generation 1α process nodes. Initial results from testing of the 1β show generational performance improvement and approximately 15% efficiency gains compared to prior leadership 1α-built parts. These types of gains will be very welcome to the performance-hungry but power-conscious mobile market customers who are now getting the first LPDDR5X built on 1β nodes.

Often, the company with the most advanced nodes can build the densest, lowest power or most efficient (power per bit) components. As a result, while products such as memory are largely standardized by JEDEC, there are benefits to sourcing with companies such as Micron that have the most advanced process nodes.

Stating the obvious: It is incredibly hard to manufacture leading-edge semiconductors. It starts with the requirements for multibillion-dollar, incredibly clean facilities that can manufacture microscopically small components with unparalleled precision and amazing consistency. But that is just the start. It also requires unmatched innovation from the brilliant minds that design the devices and the materials, processes and tools needed to build them — the nodes.

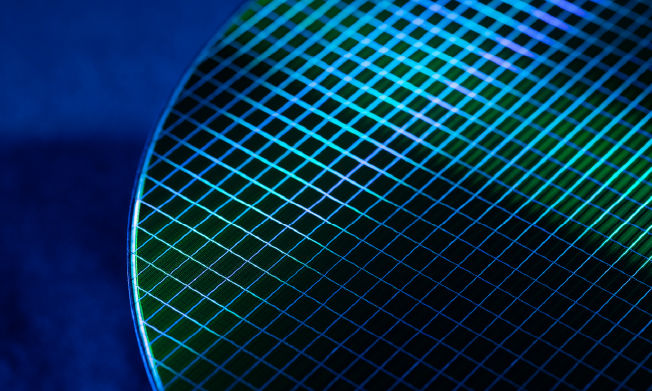

More than a thousand separate process and measurement steps are required to build advanced semiconductors such as Micron 1β DRAM. In each step along the way, one or more advanced (and expensive!) machines are performing critical, incremental and precise activities required to place atom-thin, ultrapure materials that make up each transistor of each of the hundreds of die per wafer. These die are then tested, separated and packaged as the memory modules we’ve all seen on DIMMs in our computers or in the electronics devices we use every day. In addition, circuit design innovation is critical for delivering lower-power and higher-speed products. Process technology and circuit design must be harmonized and optimized through a massive amount of validation work.

That’s where we are today with 1β process technology. We’ve taken the manufacturing steps and now shipped the first of these memory devices to our strategic smartphone customers for their development and testing work as they prepare their next generation of smartphones.

Hard work and high investment are rewarded

As a technologist, I’m always excited when my team and I reach a major milestone such as ramping a new process node. Of course, it is even more rewarding when we progress and deliver a new technology to market. Being able to see the technology in the hands of customers makes the investment of time, money and energy seem so reasonable. When we ship our initial devices, we all know that the clock starts running and we will soon see finished products from our partners and customers in the market — and that is when our accomplishments really hit home.

We know we’ve delivered this first-to-market breakthrough with 1β node technologies, but we take great pride in being able to point to some of the most in-demand phones and other devices on the market and know our technology is helping to make these devices possible.

With the first 1β-equipped smartphones in full development and qualification, we can now turn our full focus to the next tasks at hand: proliferating the process technology across a broader portion of our portfolio beyond the initial LPDDR5X components. The performance and power efficiency benefits inherent in the 1β manufacturing process promises to benefit to customers across virtually all market segments and memory technologies in our expansive portfolio.

And of course, we’ll be continuing our work on defining the next generation of process node technology — after all, this industry never stops moving forward!